Forged High Pressure High Temperature Resistant Steel Valves

There are corresponding forged steel adjusting series for gate valve, globe valve and ball valve. Die forging is used for DN15-DN80, and free forging is used for ≥ DN80. Simultaneous multidirectional die forging(Hollow silver manufacturing technology) is also gradually applied to high-end products.

Features

1.Finite element analysis aided design to optimize product strength and weight.

2.Welding bonnet, bolted bonnet and pressure self sealing bonnet can be provided according to customer requirements.

3.According to customer demand, we can provide large-diameter multi direction die forging products.

4.It can cover all cast steel series valves of the company, including valve type, pressure, diameter and material, connection mode and transmission mode.

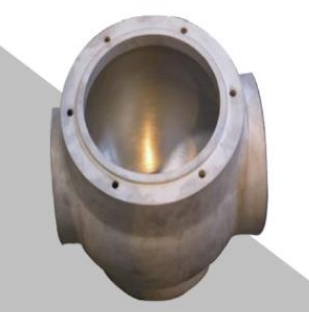

Multi direction die forging refers to the forging with complex shape, without burr, small multi branch or with cavity, which is obtained by using combined die, once heating and once stroke of the press. Moreover, there is a very high requirement for the tonnage of forging press. In the past, due to the large size of the large diameter adjusting body, it can only be made by dividing silver and then assembled and welded together. If multi-directional die forging is used, not only the shape can be directly forged in one heat, but also the inner cavity can be forged together, greatly improving the strength and aesthetics of the blank in the fiber direction, and reducing the product cost.

Process difference between forged valve and cast valve

For valve casting and valve forging, each process has its own advantages. Some projects prefer one method over the other. And the other is more suitable for other people. Below we list the main differences between casting and forging:

1. Strength difference:

Cast materials have low strength because they are poured into a cavity that allows the material to form freely.

Forged materials are stronger. Because they have a well-defined grain structure, compression by force increases their mechanical strength.

2. Suitable for hollow shapes

Casting is generally preferred for producing materials containing hollow spaces or cavities.

Forging excludes cavities and porosity from its composition.

3. The uniformity is different:

Casting materials are not always homogeneous.

Forged materials can be made into a consistent shape and maintain structural consistency.

4. Size limit:

Casting does not have any size or shape limitations. Because all materials will be melted before forming.

Materials weighing up to 50 kg can be forged. Higher power is required if the material to be forged weighs more than 50 kg. In this case casting would be the alternative.

5. Complexity

Casting can produce complex patterns and shapes. Forging focuses more on producing uniform and simple materials.

6. Different costs:

Casting uses relatively inexpensive equipment. Machines used for forging, such as heavy industrial dies, are more expensive.

This is a research paper where researchers at the University of Toledo compared the difference between one product produced in two ways. The following conclusions are listed:

The tensile strength of forgings is 26% higher than that of castings.

The fatigue strength of forgings is 37% higher than that of castings.

The yield strength of cast iron is only 66% of that of wrought steel.

The forgings had a 58% reduction in area when pulled to failure. The area of the casting was reduced by 6%.