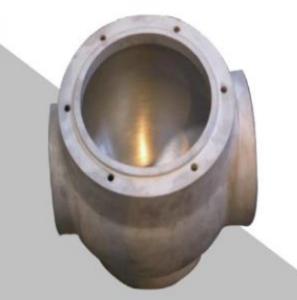

Froging Steel Valve

Features

- Finite element analysis aided design to optimize product strength and weight.

- Welding bonnet, bolted bonnet and pressure self sealing bonnet can be provided according to customer requirements.

- According to customer demand, we can provide large-diameter multi direction die forging products.

- It can cover all cast steel series valves of the company, including valve type, pressure, diameter and material, connection mode and transmission mode.

Multi direction die forging refers to the forging with complex shape, without burr, small multi branch or with cavity, which is obtained by using combined die, once heating and once stroke of the press. Moreover, there is a very high requirement for the tonnage of forging press. In the past, due to the large size of the large diameter adjusting body, it can only be made by dividing silver and then assembled and welded together. If multi-directional die forging is used, not only the shape can be directly forged in one heat, but also the inner cavity can be forged together, greatly improving the strength and aesthetics of the blank in the fiber direction, and reducing the product cost.