GB Butterfly Valve

Features

1. Three confidence structure, the butterfly plate and the seat adjustment can be connected or separated instantly, truly realizing zero wear and zero leakage.

2. Because the sealing egg adjuster is completely embedded in the butterfly plate, the whole regulating valve can be removed without any grid during maintenance, which is convenient for replacement and greatly reduces the maintenance cost.

3. The sealing surface of soft and hard laminated stainless steel sheet and flexible graphite plate (graphite rubber plate, asbestos rubber plate, etc.

4. The sealing surface of the valve seat is made of hard alloy, which makes the sealing surface wear resistant and has a long service life. It can be opened and closed continuously for more than 10000 times without damage injuries.

5. The valve shall be resistant to low (high) temperature and corrosion by selecting appropriate materials.

6. As all refractory materials are used, they have reliable fire resistance.

The three confidence structure enables the valve to have self-locking function. When the butterfly plate is closed to the sealing position, self-locking is realized immediately, and no fault occurs when the butterfly plate is closed.

8. The valve is easy to dry, the output torque is low, the streamline shape of the butterfly plate is not calculated, and the pressure lift loss coefficient is low, which can be described as an energy-saving product.

9. The sealing seat adjustment is adjustable, which is conducive to assembly and maintenance. The cut-off medium can be closed, or the medium flow can be adjusted at will.

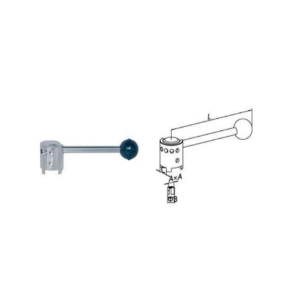

10. The connecting mode of the valve and the pipeline is flange and joint connection, which can be manual or electric, pneumatic, hydraulic electric, pneumatic and hydraulic linkage.

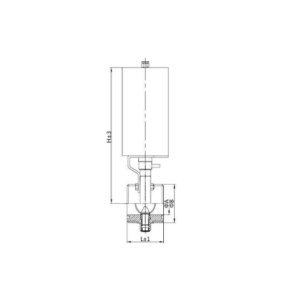

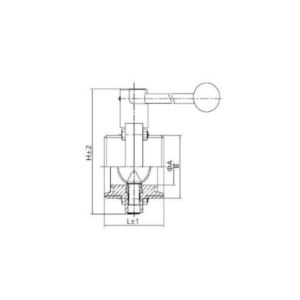

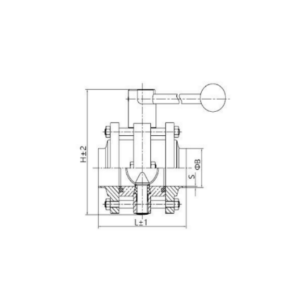

• Product Standard: GB/T 12238, JB/T 8527

• Nominal Pressure: PN6-PN160

• Nominal Dimension: DN100~DN3000

• Main Material:WCB, CF8, CF8M, LCB, LC1, WCC, WC6, WC9, CF3, 4A , 5A ,inconel625, Alloy20, Monel, Incoloy, Hastelloy, C5, Ti

• Operating Temperature: - 60℃~450℃

• Applicable Intermediaries: Water, Vapour,etc.

• Connection Mode: Flange,Wafer,Lug,Butt welding

• Transmission Mode:Manual, Electric, Pneumatic, Hydraulic/Electro hydraulic pneumatic linkage