Petroleum & Petrochemical Butterfly Valve

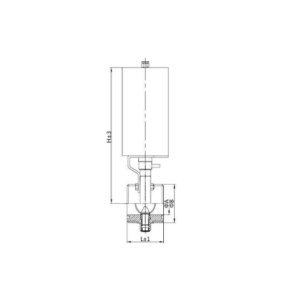

Model 1

GB Turbine Inlet Valve-Hydraulic Control Ball(Butterfly) Valve

Features:

1. The electrical control system adopts PLC intelligent control, which greatly simplifies the electrical circuit and has strong fault self diagnosis function. It can be controlled locally and remotely, and connected to the central control room and hydraulic turbine dynamic control, high degree of automation, safety and reliability, is the ideal equipment to realize the management concept of "few people on duty, no one on duty" of hydropower station.

2. The hydraulic control system uses an accumulator to store energy. When the hydropower station is powered off and there is no power supply, the accumulator releases energy, which can realize emergency dynamic water shutdown and ball adjustment, providing sufficient safety guarantee for the safe operation of the unit.

3. The applicable water head range is wide, and the maximum water head can reach 1600m.

4. The positive force of fluid is small, and that of ball(butterfly) valve is the smallest among all valves. After the valve is fully opened, the flow passage is smooth and the hydraulic loss is small.

5. Quickly switch, as long as the ancestral pole is rotated by 90°, the ball (butterfly) can be fully opened or closed.

6. The valve rod seal is reliable. When the ball (butterfly) is opened and closed, the valve rod only rotates, so the packing seal of the valve rod is not easy to be damaged, and the sealing force of the inverted seal of the regulating rod increases with the increase of the medium pressure.

• Product Standard: GB/T 14478, JB/T 12620

• Nominal Pressure: PN25-PN100

• Nominal Dimension: DN300~DN1000

• Main Material: .WCB,A105

• Operating Temperature: -29℃~120℃

• Applicable Intermediaries: Water

• Connection Mode: Flange

• Transmission Mode: Electro hydraulic pneumatic linkage

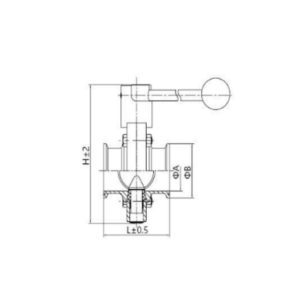

Model 2

GB Butterfly Valve

Features:

1. Three confidence structure, the butterfly plate and the seat adjustment can be connected or separated instantly, truly realizing zero wear and zero leakage.

2. Because the sealing egg adjuster is completely embedded in the butterfly plate, the whole regulating valve can be removed without any grid during maintenance, which is convenient for replacement and greatly reduces the maintenance cost.

3. The sealing surface of soft and hard laminated stainless steel sheet and flexible graphite plate (graphite rubber plate, asbestos rubber plate, etc.

4. The sealing surface of the valve seat is made of hard alloy, which makes the sealing surface wear resistant and has a long service life. It can be opened and closed continuously for more than 10000 times without damage injuries.

5. The valve shall be resistant to low (high) temperature and corrosion by selecting appropriate materials.

6. As all refractory materials are used, they have reliable fire resistance.

The three confidence structure enables the valve to have self-locking function. When the butterfly plate is closed to the sealing position, self-locking is realized immediately, and no fault occurs when the butterfly plate is closed.

8. The valve is easy to dry, the output torque is low, the streamline shape of the butterfly plate is not calculated, and the pressure lift loss coefficient is low, which can be described as an energy-saving product.

9. The sealing seat adjustment is adjustable, which is conducive to assembly and maintenance. The cut-off medium can be closed, or the medium flow can be adjusted at will.

10. The connecting mode of the valve and the pipeline is flange and joint connection, which can be manual or electric, pneumatic, hydraulic electric, pneumatic and hydraulic linkage.

• Product Standard: GB/T 12238, JB/T 8527

• Nominal Pressure: PN6-PN160

• Nominal Dimension: DN100~DN3000

•Main Material:WCB,CF8,CF8M,LCB,LC1,WCC,WC6,WC9,CF3,4A, 5A,inconel625,Alloy20,Monel,Incoloy,Hastelloy,C5,Ti

• Operating Temperature: - 60℃~450℃

• Applicable Intermediaries: Water, Steam, etc.

• Connection Mode: Flange, Wafer, Lug, Butt welding

• Transmission Mode: Manual, Electric, Pneumatic, Hydraulic/Electro hydraulic pneumatic linkage

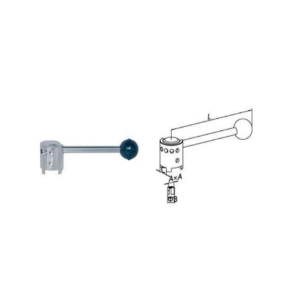

Model 3

ANSI Butterfly Valve

Features:

1. Tri-eccentricity structure, butterfly plate and adjusting seat phosphorus are indirectly deficient or separated, truly realizing zero wear and zero leakage.

2. Since the sealing ring is completely embedded in the butterfly plate, the whole regulating valve can be removed without grid during maintenance, which is easy to replace and greatly reduces the maintenance cost.

3. The sealing ring adopts the sealing surface of soft and hard laminated stainless steel sheet and flexible graphite plate (stone egg rubber plate, asbestos rubber plate, etc.), so that it has the double advantages of metal hard sealing and elastic sealing, and has excellent sealing performance no matter under low temperature or high temperature conditions.

4. Seat sealing tapered surface adopts surfacing welding carbide, which makes the sealing surface wear resistant and has a long service life. It can be opened and closed continuously for more than 10000 times without damage.

5. By selecting appropriate materials, the word gate can withstand low (high) temperature and corrosion.

6. As all refractory materials are used, they have reliable fire resistance.

7. The tri-eccentricity structure enables the valve to have a self-locking function. When the butterfly plate is closed to the sealing position, it will immediately realize self-locking, and no fault will occur when the butterfly plate is closed.

8. The valve is easy to operate, with low torque at the output end, streamlined design of butterfly plate, low pressure loss coefficient, and adjustable energy-saving product.

9. The sealing seat can be adjusted, which is conducive to assembly and maintenance. The flow can be closed or adjusted at will.

10. The connection mode between the valve and the pipeline includes flange and clip connection, which can be manual, electric, pneumatic, hydraulic or electric, pneumatic, hydraulic linkage.

• Product Standard: API6D,ASME B16.34

• Nominal Pressure: ASME CLASS150~CLASS900

• Nominal Dimension: 4”~120”

• Main Material:WCB,A105,CF8,F304,CF8M,LCB,LC1,WCC,WC6,WC9,CF3,F304L,CF3M,F316L,4A, 5A,inconel625,Alloy20,Monel,Incoloy,Hastelloy,C5,Ti

• Operating Temperature: - 60℃~450℃

• Applicable Intermediaries: Water, Steam, Oil, Natural gas,etc.

• Connection Mode: Flange, Wafer

• Transmission Mode: Handle, Worm gear, Electric, Pneumatic, Hydraulic, Electro hydraulic pneumatic linkage

Model 4

Fluorine Butterfly Valve

Features:

Two-way sealing, anti leakage double sealing structure, service life≥5000 times, corrosion resistance, full bore, low torque, light weight, rapid river opening, no boiling of media.

• Product Standard: API609,GB/T12238,GB/T26144,HG/T3704

• Nominal Pressure: CLASS150,PN10,PN16

• Nominal Dimension: DN50~DN1200

• Main Material: WCB,SG iron, Stainless steel

• Operating Temperature: -29℃~180℃

• Applicable Intermediaries: Nitric acid, Vitriolic acid,Hydrochloric acid

• Connection Mode: Flange, Wafer, Lug (ASMEB16.5,GB9113,EN1092)

• Transmission Mode: Manual, Worm gear, Electric, Pneumatic

|

Dimension |

2” |

2.5” |

3” |

4” |

5” |

6” |

8” |

10” |

12” |

14” |

16” |

18” |

|

DN50 |

DN 65 |

DN 80 |

DN 100 |

DN 125 |

DN 150 |

DN 200 |

DN 250 |

DN 300 |

DN 350 |

DN 400 |

DN 450 |

|

|

Torque (N▪m) |

33 |

50 |

72 |

82 |

117 |

195 |

260 |

390 |

559 |

715 |

780 |

1040 |