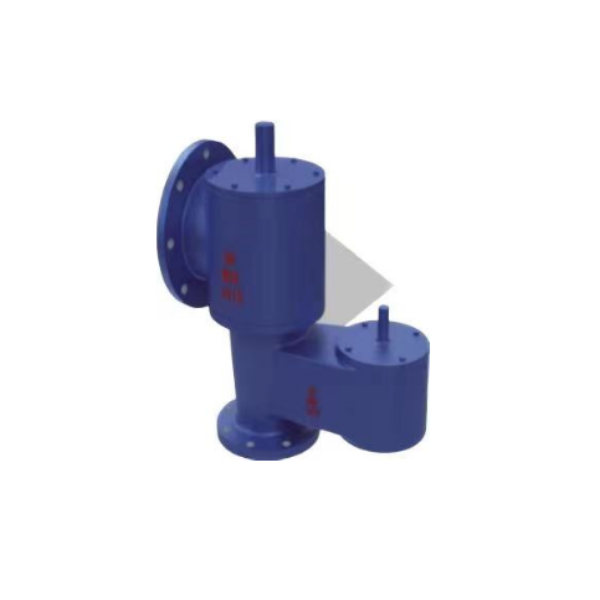

Pipe Discharge Breathing Valve

Features

Tank evaporation is a common problem in industries that handle liquids, such as oil, chemicals, and pharmaceuticals. When the liquid level in the tank drops, the space above it is filled with air. This air can contain moisture, which can condense on the walls of the tank, causing corrosion and contamination of the stored liquid. Additionally, the air can contain volatile organic compounds (VOCs), which can escape into the environment and pose a risk to human health and the environment. To prevent these issues, tanks need to be equipped with a breathing valve that allows air to enter and exit the tank without compromising the quality of the stored liquid.

One solution for tank evaporation is the pipe discharge breathing valve. This type of valve is designed to allow air to enter and exit the tank through a pipe that is connected to the valve. The valve is typically located on the top of the tank and is designed to open and close automatically based on the pressure inside the tank. When the tank is being filled, the valve remains closed to prevent liquid from escaping. When the tank is being emptied, the valve opens to allow air to enter the tank and prevent vacuum formation.

1. It can avoid the loss of the tank due to overpressure or negative pressure, and can recover the "breathing" of the tank evaporation loss of.

2.Functional structures such as flame arrester and jacket can be added according to user requirements.

• Product Standard: API2000,SY/T0511.1

• Nominal Pressure: PN10, PN16,PN25,150LB

• Opening Pressure: <1.0Mpa

• Nominal Dimension: DN25~DN300(1”~12”)

• Main Material: WCB,CF8,CF3,CF8M,CF3M,Aluminium alloy

• Operating Temperature: ≤150℃

• Applicable Intermediaries: Volatile gas

• Connection Mode: Flange

• Transmission Mode:Automatic