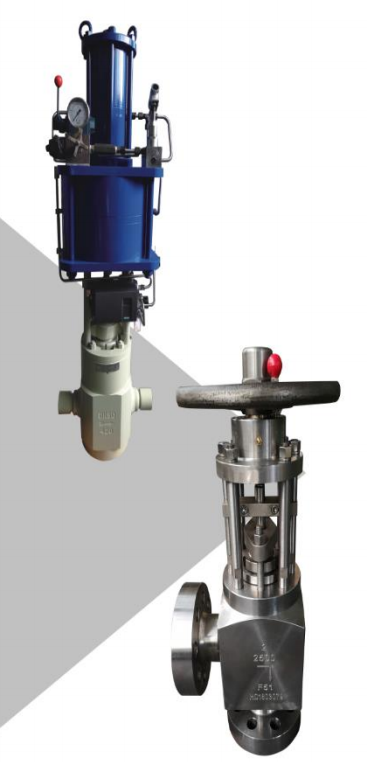

Power Station Attemperating Water Control Valve

Model 1

Features:

With wide internal multistage throttling, cage type throttling sleeve is matched with needle type wide core, which can withstand large differential pressure. The adjusting seat is pressed and sealed independently, and the conical sealing surface is reliable. It can be matched with the non-equilibrium adjusting core to achieve zero leakage. The inner part is hardened with stainless steel, which is erosion resistant and has a long service life. The single stage pressure difference is relatively reduced, so that the regulation range is expanded. Especially in small flow, it still has good regulation performance. The pressure drop of each stage shall be controlled within the critical pressure difference without cavitation and flash. The clearance with the core adjustment is reasonable, and the guide sleeve is equipped with good guide performance and stable operation. The valve is flexible in operation and accurate in adjustment.

Applications:

Boiler overheater, reheater, spray desuperheating system, low pressure bypass water spray desuperheating system. Water spray desuperheating system and pressure regulator for desuperheating products and section. The valve is able to adjust the small flow, with large adjustment range and stable operation.

• Nominal Pressure: PN16-PN320

• Nominal Dimension: DN20~DN100

• Adjusting Range: 10:1-100:1

• Main Material: WCB,A105,12Cr1MoV

• Operating Temperature: -29℃~570℃

• Applicable Intermediaries: Water

• Connection Mode: Flange, Welding

• Transmission Mode: Electric(linear motion or angular travel), Pneumatic

Model 2

Power Station High Pressure Minimum Flow Control Valve

Features:

The valve can be continuously adjusted within the range of high differential pressure; Multi stage throttling is adopted, the medium is gradually depressurized, and the pressure drop of each stage is within the range of gasification pressure drop, with cavitation resistance and low noise. The core adjustment adopts a non flat street structure, with a monotone seat and a tapered seal, which has good sealing performance and can achieve zero pool leakage. The sleeve structure is porous cage type, and the small holes are arranged strictly according to the required adjustment characteristics. With reasonable coordination between the valve core and the sleeve adjusting seat, the adjustment process has less leakage, and accurately adjustment. The upper and lower parts of the adjusting core are equipped with guide sleeves, which ensure stable adjustment, no vibration, and strong self-cleaning capability. Labyrinth structure, medium axial flow, stepwise pressure reduction through multistage throttle disc, gasoline resistant, low noise and stable operation.

Applications:

The minimum flow regulating valve is used for the return a part of the flow to the deaerator tank when the unit load is small to prevent the feed pump from overheating and gasification, and ensure the normal operation of the feed pump. This valve is mainly developed and designed for the characteristics of large feed recirculation pressure difference, poor operating conditions, high medium flow rate, and large erosion and cavitation of internal parts. It can be used together with the boiler feed pumps of 100MW/125MW/200MW/500MW units.

• Nominal Pressure: PN100-PN320

• Nominal Dimension: DN20~DN150

• Adjusting Range: 10:1-100:1

• Main Material: WCB,A105,25#

• Operating Temperature: -29℃~570℃

• Applicable Intermediaries: Water

• Connection Mode: Flange, Welding

• Transmission Mode: Electric, Pneumatic

Model 3

Power Station High Pressure Water Control Valve

Features:

The valve cover adopts white sealing structure or flange type, cage type sleeve plunger core adjustment, single seat cone seal, and high leakage level. The sealing surface is made of cemented carbide, and the surface of the inner part is sprayed with a single impact resistant material, with a long service life. The seal is metal wound gasket and reinforced flexible stone ink, reliable sealing.

Applications:

It is used for water supply flow regulation, with reliable sealing, high leakage level and long service life. Water supply bypass, spray desuperheating system. Main water supply regulation of boiler.

• Nominal Pressure: PN16-PN420

• Nominal Dimension: DN20~DN250

• Adjusting Range: 10:1-100:1

• Main Material: WCB,WC6,A105

• Operating Temperature: -29℃~570℃

• Applicable Intermediaries: Water

• Connection Mode: Flange, Welding

• Transmission Mode: Electric(linear motion or angular travel)

Product Display