Stainless Steel Precision Casting/Investment Casting Ball

Types

fixed ball

Fixed with handle ball

Two-way fixed ball

Three-way fixed ball

four-way ball

curved ball

solid ball

semi-fixed ball

floating valve ball

hollow ball

V-shaped ball

L/T/positioning ball and soft sealing tee ball, etc.

The principle of sphere spinning

Production Technical Process

(1) Casting

This is a traditional processing method, which requires a complete set of smelting, pouring and other equipment, as well as larger workshops and more workers, large investment, many processes, complex production processes, and environmental pollution. The technical level of the workers directly affects the quality of the product. The problem of the leakage of spherical capillary pores cannot be completely solved, and the blank machining allowance is large and the waste is large.

(2) Forging

This is another method adopted by many domestic valve companies at present. It has two processing methods: one is to use round steel to cut, heat and forge into a spherical solid blank, and then perform mechanical processing. The second is to mold the rounded stainless steel plate on a large press to obtain a hollow hemispherical blank, and then machine the welded spherical blank. This method has a high material utilization rate, but requires a high-power machine.

(3) Spinning

Metal spinning method is an advanced processing method with few chips and no chips, which belongs to a new branch of pressure processing. ), saving a lot of processing time (1-5 minutes for forming), and the material strength can be doubled after spinning. Due to the small area of contact between the rotary wheel and the work piece during spinning, the metal material is in a two- or three-way compressive stress state, which is easy to deform, and a higher unit contact can be obtained with a small power.

Stress (up to 25-35Mpa), therefore, the equipment is light in weight, and the total power required is small (less than 1/5-1/4 of the press), which has been recognized by the foreign valve industry as an energy-saving sphere processing The process plan is also suitable for processing other hollow rotating parts.

Spinning technology has been widely used and developed at a high speed in many countries. The technology and equipment are very mature and stable, and the automatic control of mechanical, electrical and hydraulic integration is realized.

Features

-Size:l/4"-6"

-Investment Casting Stainless steel ball

-Material of the ball CF8M CF8 CF3M

-Wecould produce all kinds of balls according to the requirement of our clients

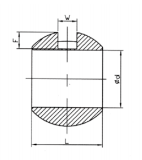

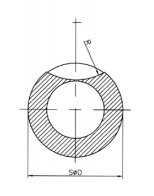

Dimension:

|

SΦD |

Φd |

L |

W |

F |

R |

|

15.5 |

9.2 |

11.5 |

4 |

2.5 |

10 |

|

20.5 |

12.5 |

15.2 |

4 |

2.7 |

10 |

|

25.5 |

15 |

19.3 |

5 |

4 |

13 |

|

32 |

20 |

23.7 |

5 |

5 |

13.6 |

|

39 |

25 |

28.5 |

8 |

5.8 |

19 |

|

42.5 |

25 |

32.9 |

8 |

7 |

20 |

|

50 |

32 |

36 |

8 |

7 |

25 |

|

60 |

38 |

45 |

9.5 |

8 |

28 |

|

63 |

38 |

48.5 |

9.5 |

9 |

30 |

|

76.5 |

50 |

56 |

9.5 |

8.5 |

28 |

|

80 |

50.8 |

59.9 |

9.6 |

10 |

37.5 |

|

97 |

65 |

70.5 |

12 |

12 |

50 |

|

100 |

65 |

73.7 |

12 |

15 |

50 |

|

115 |

76 |

84.3 |

12 |

12 |

50 |

|

120 |

76 |

90 |

12 |

15 |

50 |

|

125 |

80 |

93.7 |

16 |

15 |

37.5 |

|

148 |

94 |

112 |

15 |

14 |

62.5 |

|

152 |

100 |

111.4 |

16 |

17 |

75 |

|

194 |

125 |

145 |

20 |

24 |

50 |

|

230 |

150 |

170 |

22 |

26 |

75 |

Material List:

|

Type |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

|

CF8M |

≤ 0.08 |

≤ 1.5 |

≤ 1.5 |

≤ 0.04 |

≤ 0.04 |

18.0 ~ 21.0 |

9.0 ~ 12.0 |

2.0 ~ 3.0 |

|

CF8 |

≤ 0.08 |

≤ 2.0 |

≤ 1.5 |

≤ 0.04 |

≤ 0.04 |

18.0 ~ 21.0 |

8.0 ~ 11.0 |

|

|

CF3M |

≤ 0.03 |

≤ 1.5 |

≤ 1.5 |

≤ 0.04 |

≤ 0.04 |

17.0 ~ 21.0 |

9.0 ~ 13.0 |

2.0 ~ 3.0 |

Product Display