Stainless Steel Precision Casting/Investment Casting Sanitary Straight Ball Valve

Design Standard

Various standard valve series can be provided to customers, DIN standard series, 3A standard series, SMS standard series, ISO/IDF standard series, BS/RJT standard series, ASME/BPE and other standard series.

The components of the ball valve generally include: handle, ball with a through cavity, valve body, valve shaft and shaft seal.

The existing ball valve series specifications include: welded ball valve, clamp type ball valve, threaded ball valve and other series of ball valves.

Material:

Steel parts: SUS304, SUS316L

Sealing: PTFE, PPL

| SIZE | d | D | L | H | S |

| 1/2” | 10 | 25.5 | 75 | 41 | 95 |

| 3/4” | 17 | 50.5 | 100 | 47 | 124 |

| 1” | 22 | 50.5 | 120 | 62 | 132 |

| 1-1/4” | 28 | 50.5 | 130 | 66 | 137 |

| 1-1/2” | 35 | 50.5 | 140 | 76 | 154 |

| 1-3/4” | 42 | 64 | 150 | 84 | 160 |

| 2” | 47.5 | 64 | 164 | 91 | 173 |

| 2-1/4” | 53 | 77.5 | 164 | 93 | 173 |

| 2-1/2” | 60 | 77.5 | 190 | 97 | 173 |

| 3” | 72 | 91 | 215 | 106 | 234 |

| 3-1/2” | 80 | 106 | 225 | 125 | 244 |

| 4” | 100 | 119 | 260 | 164 | 244 |

| 5” | 125 | 145 | 320 | 210 | 350 |

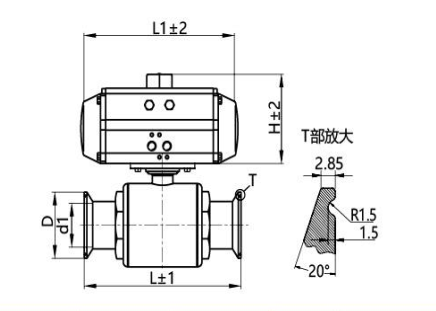

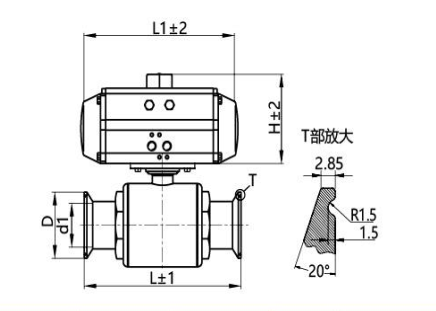

Sanitary Pneumatic Straight Ball Valve

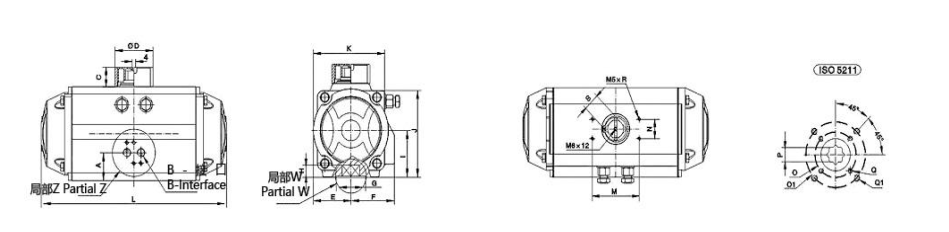

Horizontal Pneumatic Actuator

| Model | WH050

D/S |

WH063

D/S |

WH075

D/S |

WH083

D/S |

WH105

D/S |

WH125

D/S |

WH140

D/S |

|

| Size(mm) | L | 140.5 | 158.5 | 210.5 | 247.5 | 268.5 | 345 | 408.5 |

| J | 69 | 85 | 102 | 115 | 127 | 157 | 177 | |

| E | 29 | 36 | 42.5 | 49.5 | 56 | 69.5 | 80 | |

| F | 41.5 | 47 | 52 | 56.8 | 67 | 82 | 91.5 | |

| S | 11 | 11 | 19 | 19 | 19 | 27 | 27 | |

| I | 34.5 | 42.5 | 51 | 57.5 | 63.5 | 78.5 | 88.5 | |

| Remarks | P | 9 | 11 | 17 | 17 | 17 22 | 27 | 27 |

|

SIZE |

d |

D |

L |

Cylinder Model |

|

1/2” |

10 |

25.5 |

75 |

AT40 |

|

3/4” |

17 |

50.5 |

100 |

AT52 |

|

1” |

22 |

50.5 |

120 |

AT63 |

|

1-1/4” |

28 |

50.5 |

130 |

AT63 |

|

1-1/2” |

35 |

50.5 |

140 |

AT75 |

|

1-3/4” |

42 |

64 |

150 |

AT75 |

|

2” |

47.5 |

64 |

164 |

AT83 |

|

2-1/4” |

53 |

77.5 |

164 |

AT83 |

|

2-1/2” |

60 |

77.5 |

190 |

AT92 |

|

3” |

67 |

91 |

210 |

AT105 |

|

3-1/2” |

86 |

106 |

230 |

AT105 |

|

4” |

100 |

119 |

260 |

AT125 |

|

5” |

125 |

145 |

320 |

AT140 |

Sanitary Three Way Ball Valve

Type 1

Working Principle and Application:

The flow direction of the three-way ball valve is divided into T-shaped and L-shaped. By rotating the T-shaped 360°, the three orthogonal pipes can be connected to each other or the flow direction of any one of the pipes can be cut off, and the flow direction can be divided and merged. The L-type three-way ball valve can only connect two pipes that are orthogonal to each other, and cannot keep the third pipe connected at the same time. can only play a distribution role. The three-way ball valve is mainly used to cut off, distribute and change the flow direction of the medium.

Material:

Steel parts: SUS304, SUS316L

SEAL: PTFE, PPL

T-Type gateway

A inlet

90° rotation direction

|

Size |

d1 |

d2 |

D |

L |

K |

H |

S |

|

3/4” |

17 |

17 |

50.5 |

105 |

50.5 |

56 |

102 |

|

1” |

22 |

22 |

50.5 |

120 |

60 |

62 |

142 |

|

1-1/4” |

29 |

29 |

50.5 |

130 |

66 |

74 |

142 |

|

1-1/2” |

35 |

35 |

50.5 |

155 |

74 |

75 |

142 |

|

2” |

47.5 |

42 |

64 |

168 |

84 |

88 |

165 |

|

2-1/4” |

53 |

52 |

77.5 |

195 |

92 |

96 |

230 |

|

2-1/2” |

59 |

67 |

77.5 |

195 |

111 |

109 |

230 |

|

3” |

72 |

66 |

91 |

215 |

116 |

112 |

230 |

|

3-1/2” |

80 |

80 |

106 |

230 |

131 |

129 |

256 |

|

4” |

100 |

94 |

119 |

260 |

147 |

164 |

332 |

|

Technical Parameters |

|||

|

Material of Metal Parts |

components in contact with the medium |

CF8/CF3M (304/316L) Casting/Forging |

Material inspection report available |

|

components not in contact with the medium |

304(1.4301) |

||

|

Material of Sealings |

Standard |

Domestic PTFE |

|

|

Options |

Import 3M |

Comply with the basic requirements of FDA177.2600/3A/UPS food, drinking water and microorganisms. |

|

|

Pressure |

Working pressure |

0-16bar |

|

|

Control air pressure |

3-8 bar |

||

|

Temperature |

Working Temperature |

PTFE: -20~+130℃ |

|

|

SterIlization Temperature |

150℃ (Max 20min) |

||

|

Surface Treatment |

Inside surface treatment |

Ra≥0.4-0.8μm |

|

|

Outside surface treatment |

Ra≥0.8-1.6μm |

||

|

Connection |

Welding Pipe Diameter |

DIN11850 -2 with 11850-1/SMS/3A/ISO series etc |

|

|

Connection Mode: Weld, Clamp, M/F thread, Flange etc. |

|||

|

Pneumatic control |

Pneumatic controller and fixed bracket |

||

|

Size |

d1 |

d2 |

D |

L |

K |

Cylinder Model |

|

3/4” |

18 |

18 |

50.5 |

104 |

50.5 |

AT52 |

|

1” |

22 |

22 |

50.5 |

118 |

60 |

AT63 |

|

1-1/4” |

29 |

29 |

50.5 |

132 |

66 |

AT63 |

|

1-1/2” |

35 |

35 |

50.5 |

154 |

74 |

AT75 |

|

2” |

47.5 |

42 |

64 |

168 |

84 |

AT83 |

|

2-1/2” |

58.5 |

54 |

77.5 |

195 |

92 |

AT92 |

|

2-3/4” |

67 |

67 |

91 |

210 |

111 |

AT92 |

|

3” |

72 |

67 |

91 |

212 |

116 |

AT105 |

|

3-1/2” |

80 |

80 |

106 |

230 |

131 |

AT125 |

|

4” |

100 |

94 |

119 |

260 |

147 |

A140 |

Type 2

Application

This type of ball valve series is a hygienic valve for material transfer control. Widely used in food, beverage processing, as well as in the pharmaceutical and chemical industries.

Working Principle

By rotating the handle 360°, a precision-made sphere with a through-cavity is driven 360° to open or close the valve to control the flow of the medium.

Connection mode:

3A/SMS/ISO/IDF/BS

|

Size |

d1 |

d2 |

D |

L |

K |

H |

S |

|

3/4” |

17 |

17 |

50.5 |

105 |

63 |

44 |

126 |

|

1” |

22 |

22 |

50.5 |

120 |

68 |

53 |

136 |

|

1-1/4” |

29 |

29 |

50.5 |

130 |

71 |

54 |

138 |

|

1-1/2” |

35 |

35 |

50.5 |

155 |

80 |

65 |

156 |

|

2” |

47.5 |

42 |

64 |

168 |

90 |

72.5 |

170 |

|

2-1/2” |

59 |

54 |

77.5 |

195 |

102 |

86 |

194 |

|

3” |

72 |

67 |

91 |

215 |

118 |

99 |

220 |

|

4” |

100 |

94 |

119 |

260 |

142 |

123.5 |

264 |

Sanitary Straight Ball Valve

Technical Parameters

All seal material meet FDA177.2600

Working Temperature: -20~135℃ (EPDM/PTFE)

Sterilization temperature: 150℃ (max.20min)

Working pressure: 1.6Mpa(16bar)

Medium: Water, Wine, Milk, Pharmacy etc

Connection Method: 3A/DIN/SMS/ISO (welding, clamp, thread, flange)

|

Size |

d1 |

d2 |

K |

H |

S |

L |

|

1/2” |

9.5 |

12.7 |

25.4 |

40 |

95 |

95 |

|

3/4” |

15.9 |

19.1 |

50.5 |

40 |

100 |

145 |

|

1” |

22.4 |

25.4 |

50.5 |

48 |

120 |

155 |

|

1-1/4” |

28 |

31.8 |

50.5 |

52 |

130 |

155 |

|

1-1/2” |

34.9 |

38.1 |

50.5 |

60 |

140 |

155 |

|

2” |

47.6 |

50.8 |

64 |

68 |

160 |

165 |

|

2-1/2” |

59.5 |

63.5 |

77.5 |

80 |

180 |

175 |

|

3” |

72.2 |

76.2 |

91 |

86 |

210 |

190 |

|

3-1/2” |

85 |

89 |

106 |

94 |

230 |

190 |

|

4” |

97.6 |

101.6 |

119 |

115 |

260 |

245 |

Sanitary Three Way Ball Valve

Applications:

The three-way ball valve is mainly used for blocking, distributing and changing the moving direction of the medium in the pipeline. Ball valve is a new type of valve that has been widely used in recent years, widely used in food and beverage, pharmaceutical, petroleum, chemical, biological processing and other industries.

Technical Parameter

EN10204 3.1B Certificate

Using imported sealing materials, all sealing materials comply with FDA 177.2600

Working Temperature: -20~135℃ (EPDM/PTFE)

Sterilization temperature: 150℃ (max.20min)

Working Pressure: 1.6Mpa (16bar)

Medium: Water, Wine, Milk, Pharmacy, etc

Connection Method: 3A/DIN/SMS/ISO (Welding, Clamp, Thread)

Main Parts and Materials

| Pneumatic valve bodyCF3/CF8M | Valve BodyCF3/CF8M | Cap304/316L | SeatPTFE | Ball L/T304/316L | Stem304/316L | Bolt304 | Handle304 |

|

|

|

|

|

|

|

|

|

DIN dimension

|

SIZE |

Dn |

Rd |

A |

E |

F |

|

DN25 |

25 |

Rd58x1/6” |

140 |

50 |

146 |

|

DN32 |

31 |

Rd65x1/6” |

156 |

64 |

185 |

|

DN40 |

37 |

Rd78x1/6” |

172 |

68 |

185 |

|

DN50 |

49 |

Rd95x1/6” |

182 |

95 |

243 |

|

DN65 |

66 |

Rd110x1/4” |

196 |

104 |

243 |

|

DN80 |

81 |

Rd130x1/4” |

256 |

122 |

273 |

|

DN100 |

100 |

Rd160x1/4” |

286 |

173 |

273 |

SMS type

|

SIZE |

Dn |

Rd |

A |

E |

F |

|

1” |

22.4 |

Rd40x1/6” |

140 |

64 |

185 |

|

1-1/4” |

28.8 |

Rd48x1/6” |

156 |

64 |

185 |

|

1-1/2” |

35.1 |

Rd60x1/6” |

165 |

68 |

185 |

|

2” |

47.8 |

Rd70x1/6” |

182 |

73 |

205 |

|

2-1/2” |

59.5 |

Rd85x1/6” |

196 |

95 |

243 |

|

3” |

72.2 |

Rd98x1/6” |

225 |

104 |

243 |

|

4” |

97.6 |

Rd128x1/4” |

286 |

173 |

273 |

Sanitary Butterfly-Type Ball Valve

Application:

QF7 butterfly ball valve is a kind of valve which can quickly install and easy cleaning. It is the best choice for handling viscous or particulate media in sanitary industry. Mainly used in food, beverage processing and pharmaceutical and chemical industries.

Technical Parameter

EN10204 3.1B Certificate

Using imported sealing materials, all sealing materials comply with FDA 177.2600

Working Temperature: -20~135℃ (EPDM/PTFE)

Sterilization temperature: 150℃ (max.20min)

Working Pressure: 1.0Mpa (10bar)

Medium: Water, Beverage, Milk, Pharmacy, etc

Connection Method: 3A/DIN/SMS/ISO (Welding, Clamp, Thread)

Working Principle

This type of valve can be remotely operated by electric or pneumatic actuators, or manually controlled by a handle.

Electric or pneumatic actuators convert the axial motion of a piston into a 90° rotation of the valve shaft to open or close, and to control and open/close the fluid in the pipeline. Pneumatic actuator units are available in three standards: normally open(NO), normally closed(NC), and pneumatic/pneumatic (A/A).

The multi-position handle for duckbill manual operation can mechanically lock the valve in 12 positions of open or closed by adjusting the position of 15°, which can achieve the purpose of controlling the flow of the medium.

The lever-type manual operation handle mechanically locks the valve in its 4 positions of opening or closing through 4 multi-function positioning, and also achieves the purpose of controlling the flow of the medium.

|

Technical Parameters |

||

|

Material of Metal Parts |

components in contact with the medium |

304L/316L(1.4307/1.4404) |

|

components not in contact with the medium |

304(1.4301) |

|

|

EN10204 3.1B certificate available |

||

|

Material of Sealing |

Standard |

PTFE/EPDM |

|

Options |

FPM/PTFE, HNBR/PTFE, SILICONE/PTFE |

|

|

All sealing material meet FDA177.2600 |

||

|

Pressure |

Working pressure |

10 bar |

|

Temperature |

Working Temperature |

EPDM/PTFE: -20~+135℃ |

|

Sterilization Temperature |

150℃ (Max 20min) |

|

|

Surface Treatment |

Inside surface treatment |

Ra≤0.8μm |

|

Outside surface treatment |

Ra 1.6μm |

|

|

Connection |

Standard |

DIN11850 series 2 |

|

Weld End: INCH pipe standard |

||

|

Connection Mode: Weld, Clamp, thread, Flange etc. |

||

|

DN |

d |

D |

L1 |

L |

H |

H1 |

H2 |

W |

W1 |

B |

|

DN25 |

26 |

90 |

40 |

80 |

70 |

230 |

160 |

120.5 |

AT63 |

Rd52x1/6” |

|

DN40 |

38 |

100 |

50 |

100 |

76 |

235 |

180 |

120.5 |

AT75 |

Rd65x1/6” |

|

DN50 |

50 |

116 |

52.5 |

105 |

95 |

270 |

195 |

156.3 |

AT83 |

Rd78x1/6” |

|

DN65 |

66 |

142 |

62.5 |

125 |

108 |

- |

220 |

156.3 |

AT92 |

Rd95x1/6” |

|

DN80 |

81 |

172 |

70 |

140 |

125 |

- |

260 |

220 |

AT105 |

Rd110x1/4” |

|

DN100 |

100 |

200 |

85 |

170 |

155 |

- |

300 |

220 |

AT125 |

Rd130x1/4” |

Sanitary non-retention ball valve

Application:

The non-retention ball valve is an all-inclusive ball seat design, which solves the problem of liquid retention in the valve body of the ball valve. The ball valve is suitable for biopharmaceutical engineering

.

|

Size |

d |

D |

L |

H |

S |

|

3/4” |

16 |

50.5 |

100 |

65 |

105 |

|

1” |

22.4 |

50.5 |

110 |

70 |

105 |

|

1-1/4” |

28.5 |

50.5 |

120 |

80 |

130 |

|

1-1/2” |

35.1 |

50.5 |

140 |

80 |

150 |

|

2” |

47.8 |

64 |

164 |

85 |

160 |

|

2-1/4” |

53 |

77.5 |

170 |

110 |

180 |

|

2-1/2” |

59.5 |

77.5 |

180 |

110 |

180 |

|

3” |

72 |

91 |

190 |

130 |

200 |

|

3-1/2” |

85 |

106 |

200 |

140 |

210 |

|

4” |

98 |

119 |

220 |

155 |

230 |

Design Features

Connection Method: Clamp/thread/welding/flange)

Simple and easy to install

Low operating torque

Washer comply with FDA177.2600

Welding thread types of clamp: DIN, SMS, ISO, IDF, BPE, RJT

Any connection can replace the valve body without changing the overall length of the valve.

Product Features

- Anti-flying stem design

- Valve body and bonnet connection with positioning step design.

- Full circulation

- Non-return design

- Stem seal packing automatic compensation device

- Shutdown device

Working Principle

By rotating the handle 90°, 360° drives the ball with a through-cavity to open or close the valve, to control the flow of the medium.

Operation Torque (N.M)

| Size | 1-3/4” | 1” | 1-1/4” | 1-1/2” | 2” | 2-1/2” | 3” | 3-1/2” | 4” |

| Torque | 6 | 10 | 12 | 14 | 20 | 40 | 75 | 90 | 110 |

Note: the actuator proposed to increase the safety margin of 20%

Sanitary 3PC Butt Weld Ball Valve

Application

The three-piece all-inclusive ball valve is a sanitary ball valve that is easy to install, disassemble and clean. It is used for gas, liquid and other material transportation. The application range of this valve includes food, beverage, pharmaceutical and chemical industries.

The full-bore and all-encapsulated valve design greatly reduces fluid resistance and residue, making this valve the best choice for handling vacuum equipment or viscous fluids.

Technical Features

All-inclusive ball valve design, no retention, high cleanliness, meet CIP, SIP sterilization and cleaning requirements, high temperature resistance 150 ℃, pressure 25bar, automatic compensation seal design, with small torque, long serving life and so on. Normal switch more than 100,000 times. It can be configured with various executive controllers, such as electric, horizontal pneumatic, stainless steel three-dimensional pneumatic, manual handle, and can also be equipped with control units, locator, position sensors, etc., as well as automatic control systems.

Surface Treatment

All surfaces are CNC machined, 0.8rn, up to RA0.4cm, electro polished up to 0.25cm.

|

Size |

d |

D |

L |

H |

S |

|

1/2” |

9.4 |

12.7 |

90 |

60 |

132 |

|

3/4” |

16 |

19 |

104 |

64.5 |

132 |

|

1” |

22.1 |

25.4 |

115 |

69 |

165 |

|

1-1/4” |

28.5 |

31.8 |

125 |

75 |

170 |

|

1-1/2” |

34.9 |

38.1 |

140 |

89 |

194 |

|

2” |

47.5 |

50.8 |

156 |

97 |

194 |

|

2-1/2” |

59.5 |

63.5 |

198 |

127 |

252 |

|

3” |

72.2 |

76.2 |

230 |

135 |

252 |

|

4” |

97.6 |

101.6 |

242 |

159 |

332 |

|

5” |

125 |

145 |

290 |

210 |

350 |

|

Size |

d |

D |

L |

H |

S |

|

1/2” |

9.4 |

25.5 |

90 |

60 |

132 |

|

3/4” |

16 |

50.5 |

104 |

64.5 |

132 |

|

1” |

22.1 |

50.5 |

115 |

69 |

165 |

|

1-1/4” |

28.5 |

50.5 |

125 |

75 |

170 |

|

1-1/2” |

35 |

50.5 |

140 |

89 |

194 |

|

2” |

47.5 |

64 |

156 |

97 |

194 |

|

2-1/2” |

59.5 |

77.5 |

198 |

127 |

252 |

|

3” |

72.2 |

91 |

230 |

135 |

252 |

|

4” |

97.6 |

119 |

242 |

159 |

332 |

|

5” |

125 |

145 |

290 |

210 |

350 |

3PC Pneumatic All-Inclusive Ball Valve

Design Standard

Various standard valve series can be provided to customers, namely for DIN standard series, 3A standard series, SMS standard series, ISO/IDF standard series, BS/RJT standard series, ASME/BPE and other standard series.

The components of a ball valve generally include: a ball with a through cavity, a valve body, a valve shaft and a shaft seal.

Existing valve series specifications are: welded, clamp and threaded

Pneumatic actuators can be installed on two-way or three-way low or high platform ball valves conforming to ISO5211 standard. Low platform ball valve can be attached with bracket mounted actuator

Material: 316, ASTM-CF8M A351

Seat: PTFE

|

Size |

d |

D |

L |

Cylinder Model |

|

1/2” |

9.4 |

25.5 |

90 |

AT40 |

|

3/4” |

16 |

50.5 |

104 |

AT50 |

|

1” |

22.1 |

50.5 |

115 |

AT63 |

|

1-1/4” |

28.5 |

50.5 |

125 |

AT63 |

|

1-1/2” |

34.9 |

50.5 |

140 |

AT75 |

|

2” |

47.5 |

64 |

156 |

AT83 |

|

2-1/2” |

59.5 |

77.5 |

198 |

AT92 |

|

3” |

72.2 |

91 |

230 |

AT125 |

|

4” |

97.6 |

119 |

242 |

AT140 |

Three pieces through ball valve

Design Standard:

The opening and closing part of the three-piece all-inclusive ball valve is a ball, and the ball is rotated around the axis of the valve stem to achieve the purpose of opening and closing. The three-piece quick-loading all-inclusive ball valve is mainly used to cut off the circulation of the medium on the pipeline.

The main features of this ball valve are reliable sealing, compact structure, easy operation and maintenance. In addition, the sanitary ball valve has the least fluid resistance, and its resistance coefficient is equal to the same length of pipe section.

The three-piece clamp ball valve is simple in structure, small in size and light in weight. It has good sealing performance and has been widely used in vacuum systems. After connecting to the pipe, cross-tighten it with the specified torque.

Technical Specifications:

Material: SS304, SS316L

Size: DIN standard: DN15-DN100

ISO standard: 3/4”- 4”

Working principle: The sanitary clamp ball valve uses the ball to rotate around the axis of the valve stem to achieve the purpose of opening and closing. It is mainly used to cut off the circulation of the medium on the pipeline.

Connection forms are: thread, flange, welding, quick connection, etc.

Application: Specially used in various industrial fields of highly corrosive media.

|

Size |

d1 |

d2 |

K |

L |

H2 |

S |

|

3/4” |

15.9 |

19.1 |

25.4 |

105 |

53 |

128 |

|

1” |

22.2 |

25.4 |

50.5 |

115 |

58 |

165 |

|

1-1/4” |

28.6 |

31.8 |

50.5 |

125 |

63 |

165 |

|

1-1/2” |

34.9 |

38.1 |

50.5 |

140 |

70 |

175 |

|

2” |

50.8 |

47.6 |

64 |

160 |

80 |

215 |

|

2-1/2” |

63.5 |

59.5 |

77.5 |

175 |

87.5 |

215 |

|

3” |

76.2 |

72.2 |

91 |

210 |

105 |

280 |

|

3-1/2” |

85 |

81 |

106 |

220 |

110 |

280 |

|

4” |

101.6 |

97.6 |

119 |

240 |

125 |

295 |

Sanitary Flange Ball Valve

Working principle: This ball valve is mainly used to cut off the circulation of the medium on the pipeline. He needs a smooth rotating operation and a small turn to close tightly. According to the driving method, it can be divided into manual ball valve, pneumatic ball valve, electric ball valve and electric proportional control valve.

Widely used in: food, beverage, chemical and other fields.

Advantages of this valve:

The flange connection improves the appearance of the previous industrial valve, adopts mechanical grinding, and the surface treatment achieves a clean surface inside and outside, which complements the advantages of food grade and industrial grade. Really solve the equipment experience of various industries spanning equipment.

|

Size |

d |

D |

L |

H |

S |

|

DN15 |

16 |

100 |

100 |

60 |

120 |

|

DN25 |

28 |

110 |

130 |

85 |

150 |

|

DN32 |

35 |

130 |

140 |

95 |

150 |

|

DN40 |

42 |

140 |

150 |

108 |

165 |

|

DN50 |

50 |

160 |

164 |

115 |

165 |

|

DN65 |

66 |

180 |

190 |

128 |

220 |

|

DN80 |

80 |

200 |

210 |

146 |

240 |

|

DN100 |

100 |

220 |

240 |

190 |

240 |

Product Display