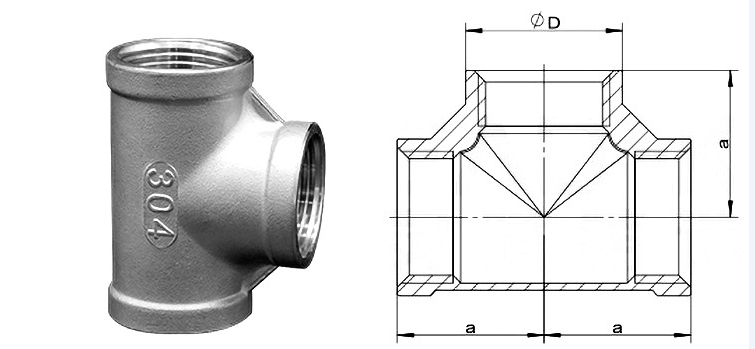

Stainless Steel Threaded Casting Fittings Tee

Main Dimension Table

|

DN |

Size |

φDmm |

Amm |

|

DN6 |

1/8” |

15 |

17.0 |

|

DN8 |

1/4” |

18 |

19.0 |

|

DN10 |

3/8” |

21.5 |

23.0 |

|

DN15 |

1/2” |

26.5 |

27.0 |

|

DN20 |

3/4” |

32 |

32.0 |

|

DN25 |

1” |

39.5 |

37.0 |

|

DN32 |

11/4” |

48.5 |

43.0 |

|

DN40 |

11/2” |

55 |

48.0 |

|

DN50 |

2” |

67 |

56.0 |

|

DN65 |

21/2” |

84 |

69.0 |

|

DN80 |

3” |

98 |

78.0 |

|

DN100 |

4” |

124.5 |

94.0 |

Thread type and standard

|

Nation |

China |

Japan |

Korea |

German |

UK |

USA |

|

Thread Type |

R RC RP G |

PT PF |

PT,PF |

R, RP |

BSPT BSPP |

NPT NPSC |

|

Standard |

GB/T7306 GB/T7307 |

JIS B0203 JIS B0202 |

KS B0221 KS B0222 |

DIN2999 |

BS21 |

ANSI/ASME B1.20.1 |

Product Display